Since September 2024, Savio Macchine Tessili S.p.A. of Italy has been working with the Recycling Atelier Augsburg. Savio will assist the Recycling Atelier with winding and yarn quality assurance. This collaboration opens up new research opportunities and completes the mechanical textile recycling process chain.

Savio Macchine Tessili S.p.A. is an expert in the yarn finishing area of textile technology. With production facilities in Italy and Asia, the Italian company provides a range of winding, twisting, air-jet spinning, shrinking, and bulking devices. It’s been in business for almost 110 years. The collaboration completes the mechanical textile recycling process chain by adding a new stage and creating research opportunities in the areas of yarn winding and quality control.

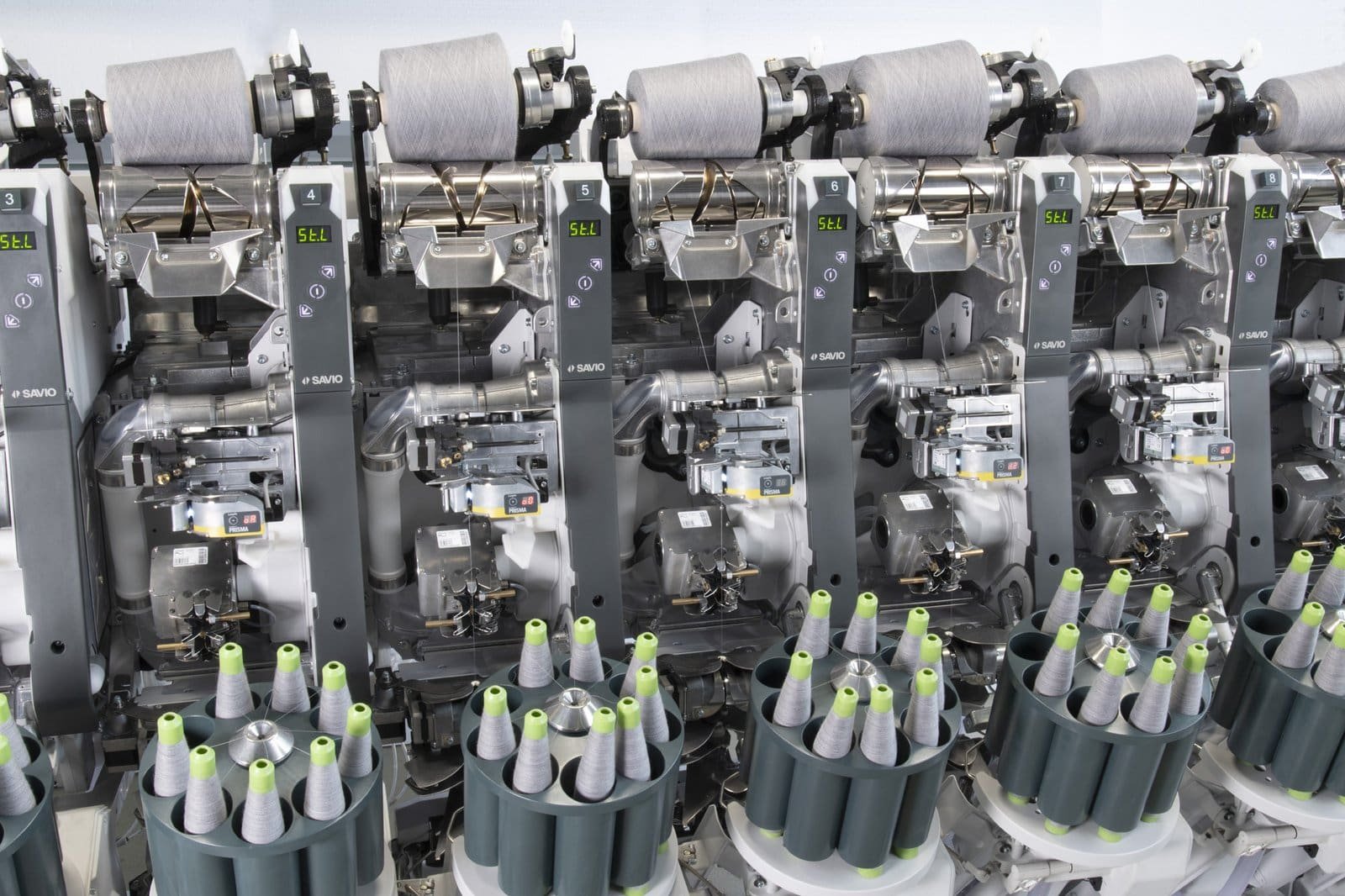

Winder “Proxima” from Savio Macchine Tessili S.p.A. Source: Savio Macchine Tessili S.p.A.

Twelve industrial businesses make up the Recycling Atelier partner network, which collectively covers the whole mechanical textile recycling process chain. Savio Macchine Tessili S.p.A. is a crucial part of the high-quality textile recycling process. Savio’s contributions go beyond simply lending their invaluable expertise in the winding industry. Additionally, the business supplies the Recycling Atelier with Proxima Smartconer® winders. The yarn’s quality is greatly influenced by the winding procedure. The final stage of spinning is winding, which allows the yarn to be regulated and qualified before proceeding to the subsequent steps of knitting, weaving, dying, and finishing.

Know-how directly from the manufacturer

Dr.-Ing. Georg Stegschuster, Head of Recycling Atelier, says: “Savio winding machines offer high productivity, low energy consumption, premium yarn quality, automation, and data connectivity. Those criteria are ideal for the setup in the Recycling Atelier. Plus, we receive insightful know-how directly from the manufacturer. We are looking forward to the cooperation and the positive impact that Savio’s involvement will bring to our applied research.”

Mauro Moro, CEO of Savio Macchine Tessili, is delighted about the partnership with the Recycling Atelier Augsburg: “The collaboration with the Recycling Atelier Augsburg is a step forward to advancing research in winding technology and quality control within the recycling context.”

Prof. Mesut Cetin, Institute Director of ITA Augsburg and professor at the Faculty of Mechanical and Process Engineering at Augsburg University of Applied Sciences, explains the impact and work of the Recycling Atelier: “The Recycling Atelier, ITA Augsburg and the Technical University of Applied Sciences Augsburg see themselves as a catalyst for industry towards sustainability. We welcome innovation and progress in any form. Whether application-oriented content or basic research, whether publicly funded projects or direct contract research – we are open to any exchange between industry and research.”

About Savio Macchine Tessili S.p.A

Over its 110+ years history, Savio acted as technological leader and innovative player in attractive niches of the textile value chain. Savio has a consolidated presence in all relevant geographies with a local-for-local approach, allowing Savio to promptly address market demand and requirements. Savio is specialized in the textile machinery sector for the yarn finishing segment being the leading supplier of winding, twisting and air-jet spinning machines with manufacturing plants in Italy, China and India.

About the Recycling Atelier

The Recycling Atelier Augsburg is the first model factory for mechanical textile recycling worldwide. The aim is to use expertise from science and industry to develop innovative solutions for high-quality textile recycling in the sense of a sustainable material cycle along the entire textile production chain. The research and development work at Recycling Atelier Augsburg covers the entire path of textile secondary raw materials – from used textiles back into high-quality products.

As part of the Augsburg AI production network, the Institute of Textile Technology Augsburg, an affiliated institute of Augsburg University of Applied Sciences, initiated this model factory for the sustainable material cycle together with THA and opened it in June 2022.

About the AI Production Network

The Augsburg AI Production Network, set up by the Bavarian state government, is a network of AI experts in the greater Augsburg area. The network partners are the University of Augsburg, the Fraunhofer Institute for Casting, Composite and Processing Technology IGCV, the Center for Lightweight Production Technology (ZLP) of the German Aerospace Center (DLR) in Augsburg and the Technical University of Applied Sciences Augsburg (THA). Regional industrial partners are also involved. The aim is to conduct joint research into AI-based production technologies at the interface between materials, manufacturing technologies, data-based modeling and digital business models. The Free State of Bavaria is funding the project with 92 million euros as part of the Hightech Agenda Plus.