SAITEX’s 2023 Impact Report, which highlights their steadfast dedication to sustainability, innovation, and social responsibility in the fashion sector, is something we are thrilled to share.

By working with top international companies, SAITEX, a leader in circular manufacturing, hopes to establish standards for environmentally friendly denim production. Their progress is transparently described in this year’s impact report, which also outlines next initiatives and contextualizes data to indicate areas for improvement. With an emphasis on environmental stewardship and social empowerment, it offers significant turning points in its regenerative methods, the application of cutting-edge technologies, and innovations that turn waste into useful products.

“We at SAITEX support open and honest accountability. Progress requires us to share our impact, both positive and negative. Setting high standards and making constant improvements when we fail are essential to our development as a circular system, according to CEO Sanjeev Bahl.

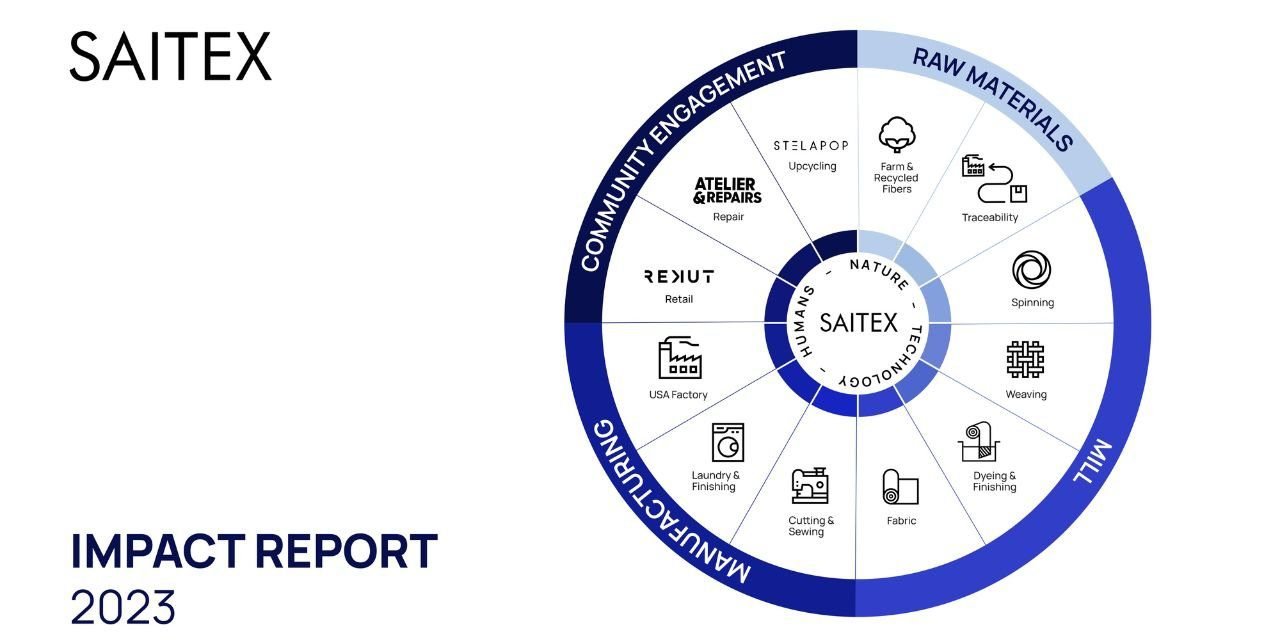

SAITEX has been human-centric and purpose-driven from its establishment in 2001, committed to improving social and environmental practices in the clothing manufacturing sector. Known as “The World’s Cleanest Denim Factory” by Bloomberg, SAITEX has established itself as a global standard for ethical and sustainable production. The organization has developed into an ecosystem throughout time, which today consists of:

- SAITEX Apparel Manufacturing in Vietnam (2006) – sustainable denim at scale

- SAITEX Los Angeles in USA (2021) – designed to address style trends with speed to market

- SAITEX Mill – clean denim fabric spinning facility in Vietnam (2022)

- STELAPOP – a division upcycling waste into consumer products (2019)

- Inclusive workforce initiative REKUT (2019)

- Denim Upcycling project Atelier & Repairs (2021)

Together, these entities share a unified vision, collaboratively redefining how denim is made and [re]used.

Modern technology and human ingenuity serve as the foundation of SAITEX’s operations, incorporating Industry 4.0 innovations such as artificial intelligence (AI), machine learning, the Internet of Things (IoT), RFID, robotics, and cloud computing. The three main pillars of sustainability and circularity—Speed-to-Market (STM), transparency, and traceability—are improved by this smart manufacturing strategy. SAITEX maps its activities through a vertically integrated ecosystem and continuous Life Cycle Assessments (LCAs) in collaboration with Ecochain since 2019. This allows for data-driven decision-making that promotes responsibility, continuous improvement, and solutions for a sustainable future.

As a partner of top international brands like G-Star, Everlane, J. Crew, Madewell, Zara, A.P.C., IKEA, and Polo Ralph Lauren, SAITEX manufactures premium denim and clothing while continuously pushing the limits of sustainability. In order to guarantee compliance with the highest standards of sustainability and accountability, SAITEX also actively collaborates with certifying organizations such as Bluesign®, GOTS, GRS, regenagri®, OEKO-TEX®, and C2CPII.

After reading the impact report, I’d be pleased to put you in touch with SAITEX CEO Sanjeev Bahl for an interview or more information on how SAITEX is evolving into the factory of the future.

SAITEX 2023 IMPACT REPORT’S KEY INSIGHTS

- By 2023, SAITEX Mill in Vietnam achieved a milestone in which 25% of all fabrics produced by the facility were Cradle to Cradle Certified® Gold denim. These fabrics are created with substantial reductions in CO2 emissions, energy usage, and water consumption, enabling brands to produce cleaner denim sustainably—all under one roof.

- Since 2021, SAITEX has been the only mill in Vietnam equipped with Smart-Indigo™ technology. After 2 years of implementation, this has reached the milestone of reduced CO2 emissions by 90%, energy use by 70%, and water consumption by 30%, marking a significant leap for SAITEX in clean denim manufacturing.

- By 2023, SAITEX’s REKUT program successfully integrated 98% of employees from marginalized backgrounds into garment production across all categories, exemplifying CEO Sanjeev Bahl’s dedication to inclusivity and equity.