Lenzing – Today, the Lenzing Group, a prominent provider of regenerated cellulosic fibers for the textile and nonwovens sectors, announced the inclusion of LENZING Lyocell Fill in its line of TENCEL fibers. With this wider range expansion, a finer variation with different cut lengths is introduced, specifically designed for filling applications in clothing and home textiles.

With the planet at heart2,4, our expanded LENZING Lyocell Fill fibers, both EU Ecolabel-certified5 and ClimatePartner-certified1, are versatile and can offer an almost endless variety of product designs and functions,” said Caroline Ledl, Senior Director of Global Product and Application Management, Commercial Textile, Lenzing AG. “These fibers provide not only enhanced thermal comfort and moisture control6 but also form keeping properties7. Leveraging our decades of experience in refining filling materials, we believe our expanded

1 LENZING™ Lyocell fibers are ClimatePartner certified as part of a bespoke climate action plan, which assesses the carbon footprint of our products, sets targets and implements measures to reduce emissions, supports verified climate projects, and fosters transparency along our supply chain. For details of ClimatePartner certification, please refer to Climate-ID pages: TENCEL™ Lyocell. 2 LENZING™ Lyocell fibers are made with at least 50% less carbon emissions and water consumption, compared to generic (unbranded) lyocell. The results were calculated according to LCA standards (ISO 14040/44) and are made available via the Higg Materials Sustainability Index (MSI) v3.9.

3 Adhering to the company’s commitment to environmental protection and resource preservation, Lenzing procures wood and pulp only from certified or controlled sustainable sources. In its Wood and Pulp Policy, Lenzing is committed to procuring wood and pulp exclusively from non-controversial sources.

4 To foster a sustainable global textile and nonwovens industry, Lenzing follows three strategic principles within the context of its “Naturally Positive” sustainability strategy, which focuses on greening the value chain, advancing the circular economy, and collaborating for systemic change with key industry stakeholders, such as Textile Exchange, Cascale, Canopy, Together for Sustainability, Renewable Carbon Initiative, and UN Global Compact.

5 LENZING™ Lyocell fibers are certified with the EU Ecolabel (license no. AT/016/001) for environmental excellence. 6 The structure of LENZING™ Lyocell fibers allows the absorption and release of moisture. In the final textile product, these effective moisture controlling properties support a drier microclimate on the skin, increasing the wearer’s thermal comfort.

7 Cafuta et al., Suitability of lyocell fiber for pillow fillings, 2018.

fiber portfolio will inspire like-minded industry partners to create even more innovative designs across various product applications.”

LENZING Lyocell Fill fibers could make it comfortable to rest on a cool mattress pad, curl up under a warm comforter, or sink into a pillow. With its efficient moisture control for a naturally dry feeling, this extended portfolio adds to the thermal comfort that is necessary to encourage greater sleep.7, 8, 9, and 10

The extended fiber range offers improved compatibility to integrate easily with other filling fibers like polyester and filling materials like down. It features two separate linear densities and a variety of cut lengths. This adaptability accommodates various filling methods and product designs, meeting a range of design and application requirements as well as individual consumer preferences in clothing, home textiles, and other areas.

The new, finer fibers improve the tactile sensation in pillows, stuffed animals, and other lightweight applications. They are appropriate for both carding and blow-fill techniques. For comforters, blankets, and other household textile applications—especially those that use carding technology—the well-established, coarser fibers continue to provide intrinsic moisture control6 and bulkiness for improved sleep comfort.

Manufacturers and consumers seeking to lower the consumption of fossil-based materials will benefit from the responsibly sourced3 and resource-efficiently produced2 LENZING Lyocell Fill fibers, which are made from wood, a natural raw material that is both gentle on the skin6 and the environment.

The expanded LENZING Lyocell Fill portfolio will be unveiled at the Lenzing booth (Hall 11, booth #A11) during Heimtextil in Frankfurt, January 14–17, 2025. Visitors can connect with Lenzing experts and discover how these innovative fibers can elevate product offerings.

Images related to the announcement can be downloaded from here.

Facts and figures

The expanded LENZING Lyocell Fill portfolio features two linear densities and five cut lengths:

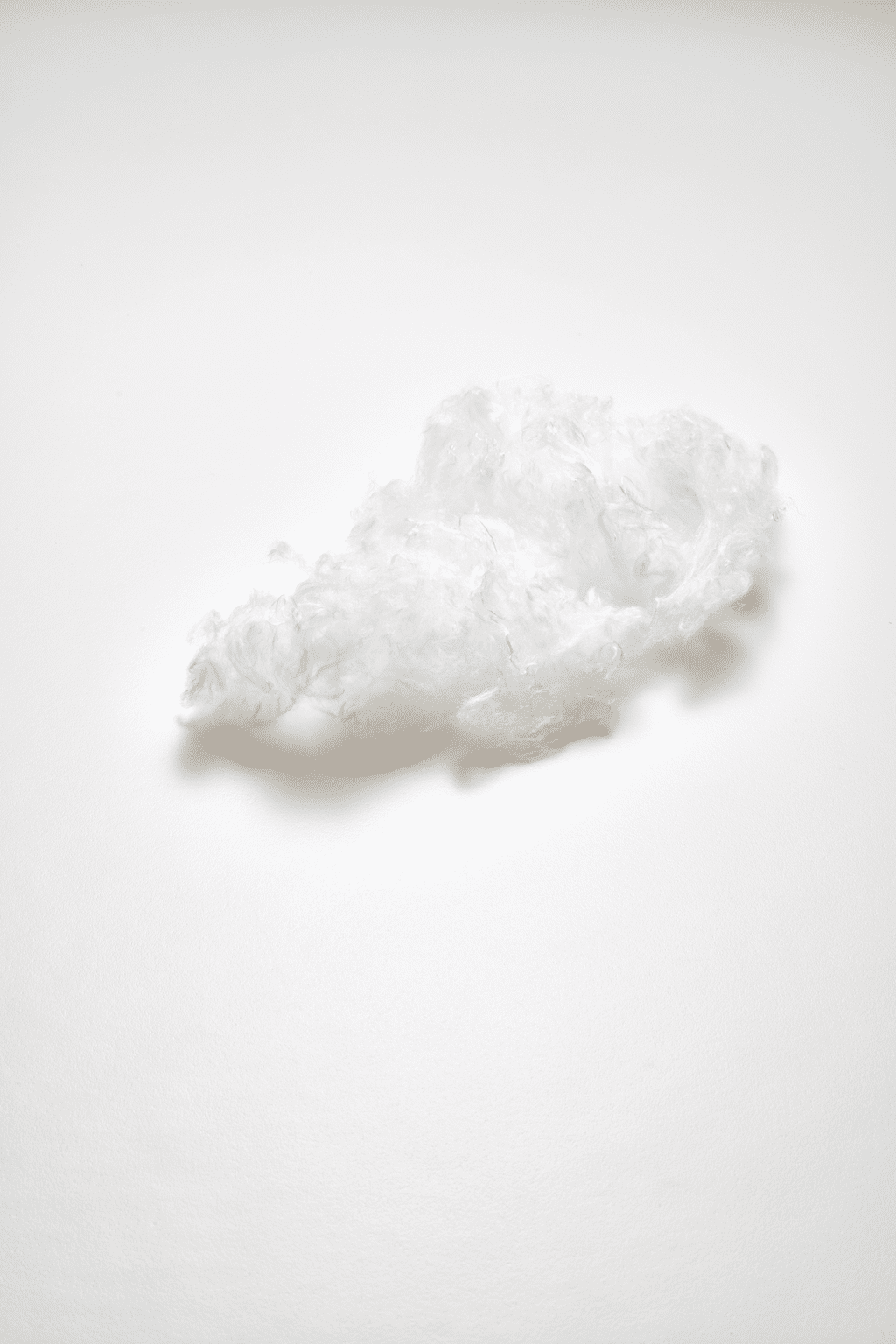

Lyocell_Fill_1.7dtex

• 1.7dtex:. Finer variant available in 60mm with options coming soon in 16mm and 32mm. Particularly suitable for blow-fill applications (e.g. pillows and stuffed toys) and blends with premium materials (e.g. down, feather and silk). The 1.7dtex/60mm variant is designed for application in apparel fillings (e.g. jackets).

Helbig, K. (2006). Comparative research: Microclimate of bedding components. Lanzinger Berichte, 85, 51-53. 9 Abu Rous M. Characterisation of the Wet-state Pore Structure of Lyocell and Other Man-made Cellulosic Fibers by Fluorescence and Electron Microscopy: Doctoral Thesis. Leopold-Franzens University Innsbruck, 2009, 185 pages.

Moser et al., Influence of textile materials on a restful sleep, 2007.

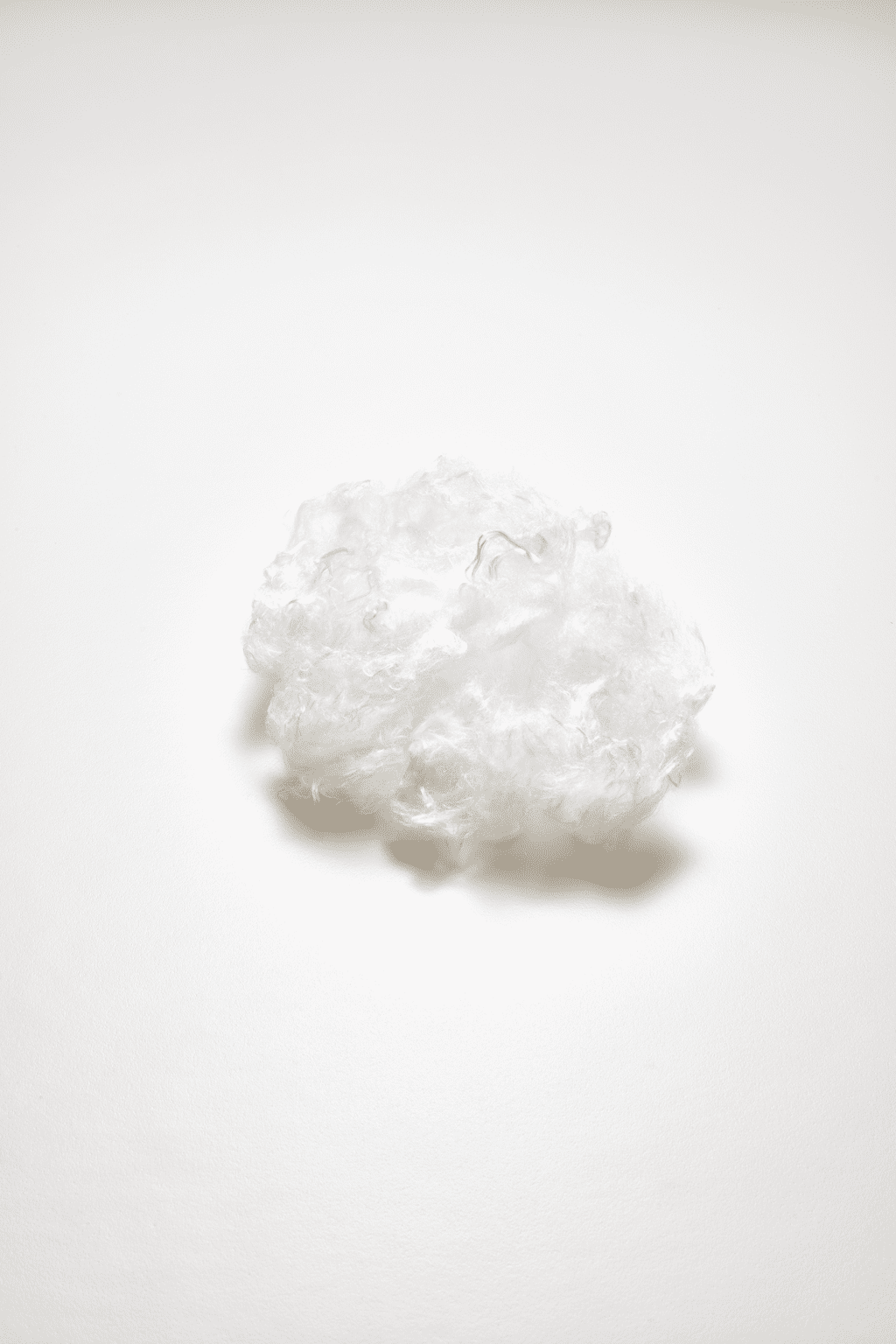

Lyocell_Fill_6.7dtex

• 6.7dtex: Established fiber for carding and blow-fill applications. Available in 32mm and 60mm cut lengths. Excels in comforters, quilts, and other home textile applications.