Sustainability in Textiles | Textile Industry

From Cotton to Carbon Cuts: Sri Kannapiran Mills’ Green Drive

Published: September 13, 2025

Author: HFT

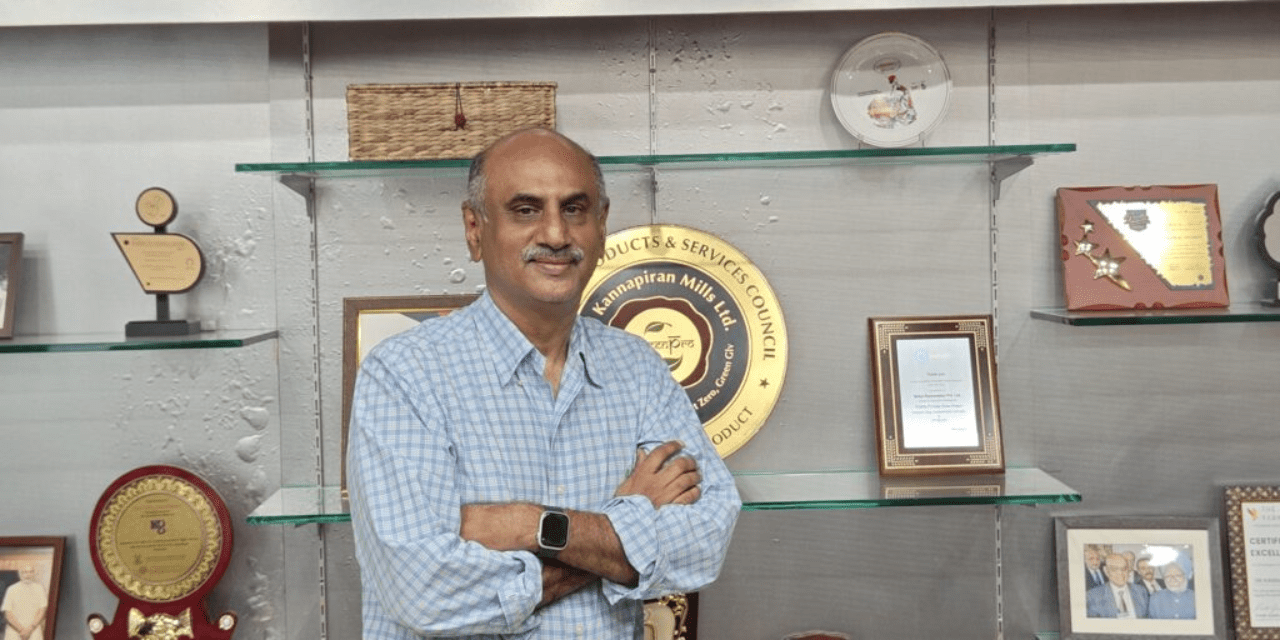

Srihari Balakrishnan, Managing Director

High-Performance Yarn Specialist

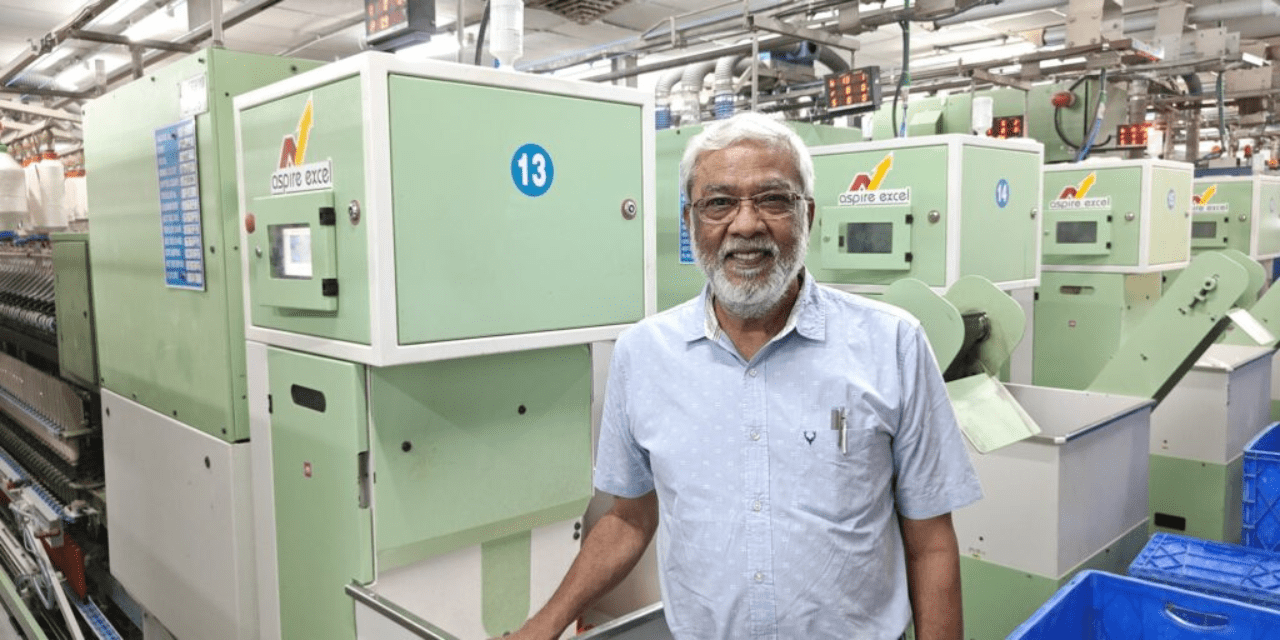

R. Seenivasahan, Vice President, Kannapiran Mills

Green Before It Was Cool

Precision Investment: Powered by Good Fashion Fund

Sustainability ≠ Solar Panels Alone

Diversification: Weaving into the Future

MMF: Still a Roadblock

Related Posts