A Comprehensive Review

By Dr. V.D.Gotmare, Ph.D (Tech.).; Hon.F.T.A.

Representative Director (India), Mumbai

Frontier.cool.Inc., Taiwan

(Former HoD, Textile Manufactures Department, V.J.T.I., Mumbai-19)

Chairman, The Textile Association (India) – Central

GC Member, TAI, Mumbai Unit

Dr. V.D.Gotmare

The textile industry, particularly in the home sector, is one of the largest and most resource-intensive industries globally. With rising concerns over environmental sustainability, the demand for sustainable practices in home textiles has never been more critical. As we move toward a more eco-conscious society, there is a significant shift toward integrating sustainable materials and processes in home textiles, such as bedding, curtains, upholstery, and other fabric-based home decor. This paper explores the latest trends in sustainable home textile materials, highlighting key innovations, practices, and challenges, along with their environmental and social impacts.

1. The Environmental Impact of Traditional Home Textiles

Home textiles are traditionally made from synthetic fibres like polyester, nylon, and acrylic, derived from petroleum-based resources. These materials, while durable and cost-effective, contribute significantly to environmental degradation. Some of the main issues associated with traditional home textiles include:

- High Water Usage: Cotton, one of the most common fibres used in home textiles, is water-intensive to grow. For instance, it can take about 2,700 litres of water to produce the cotton needed for just one t-shirt.

- Chemical Pollutants: Conventional textile production often involves harmful chemicals, including pesticides for cotton farming and toxic dyes and finishes, which contaminate waterways and harm ecosystems.

- Non-Biodegradability: Many synthetic fibres, such as polyester, take hundreds of years to degrade in landfills, adding to the global issue of waste accumulation.

- Energy Consumption: The process of manufacturing textiles, from fibre production to weaving and dyeing, requires vast amounts of energy, often derived from non-renewable sources.

In light of these environmental concerns, there has been an increasing focus on adopting more sustainable practices in the textile industry.

Source: Textile Learner

2. Sustainable Materials in Home Textiles

2.1. Natural Fibres

Natural fibres have gained prominence as eco-friendly alternatives to synthetic materials. These fibres are biodegradable and often require fewer chemicals in their production.

- Organic Cotton: Organic cotton is grown without synthetic pesticides or fertilizers, making it a more environmentally friendly option. It also uses less water and fewer chemicals compared to conventional cotton farming. Furthermore, organic cotton is often processed with environmentally friendly dyes and finishes.

- Linen: Derived from the flax plant, linen is one of the most sustainable fibres due to its low water consumption and minimal chemical use. Linen is also naturally hypoallergenic and durable, which extends its lifespan.

- Hemp: Hemp is another eco-friendly material that requires minimal water, pesticides, and synthetic fertilizers to grow. Hemp fibres are incredibly durable, and the plant is known for its ability to improve soil health, making it an ideal crop for sustainable farming.

- Bamboo: Bamboo fabric has become increasingly popular in home textiles due to its softness and sustainability. While the raw bamboo plant is eco-friendly, the process of turning bamboo into fabric often involves a chemical-intensive process unless produced through mechanical methods.

Source: Intech Open

2.2. Recycled and Upcycled Fibres

As the importance of recycling and circularity in the fashion and textile industry grows, so does the use of recycled fibres in home textiles.

- Recycled Polyester: Made from post-consumer plastic waste, recycled polyester helps reduce the need for virgin petroleum-based polyester. By reprocessing plastic bottles or discarded textiles, recycled polyester prevents waste from ending up in landfills.

- Recycled Cotton: Recycled cotton is made from discarded textiles or off-cuts from the textile production process. This reduces the need for new cotton farming, saving water and reducing pesticide use.

- Upcycled Fabrics: In upcycling, old home textiles or clothing are repurposed to create new products. This process minimises waste and reduces the need for raw materials, effectively contributing to a circular economy.

Source: Dreamstine.com

2.3. Plant-Based and Bio-Based Fabrics

Plant-based fabrics, such as those made from corn (PLA), seaweed (Alginate fibres), and mushrooms (Mycelium), are emerging as novel sustainable alternatives.

- Tencel (Lyocell): Made from sustainably sourced wood pulp, typically from eucalyptus trees, Tencel is known for its low environmental impact. The production process uses a closed-loop system that recycles water and solvents, reducing water pollution and chemical waste.

- Piñatex: This innovative fabric is made from the fibres of pineapple leaves, offering a sustainable alternative to synthetic leather. Piñatex is biodegradable, and its production supports local farming communities.

Source: Shutterstock

3. Sustainable Production Practices

Along with sustainable materials, the practices involved in textile production are critical for reducing the environmental impact of home textiles.

3.1. Low-Impact Dyeing and Finishing

The conventional dyeing and finishing processes used in textile production are highly water- and chemical-intensive. Sustainable dyeing technologies aim to minimise these impacts:

- Natural Dyes: Using plant-based or mineral dyes, such as indigo, madder, and turmeric, can significantly reduce the environmental impact. These dyes are biodegradable and non-toxic.

- Waterless Dyeing: Technologies such as waterless dyeing (e.g., CO2 dyeing) utilize supercritical CO2 to transfer dye onto fibres, eliminating the need for water and chemicals.

- Digital Printing: Digital printing reduces water and energy consumption compared to traditional printing techniques. It also allows for more precise application of dyes, reducing waste and chemical use.

3.2. Energy-Efficient Manufacturing

Sustainable home textile brands are also investing in energy-efficient machinery and renewable energy sources. The use of solar, wind, or hydroelectric power in textile mills helps reduce the carbon footprint associated with textile production.

4. Trends in Sustainable Home Textiles

4.1. Eco-Friendly Certifications and Labels

To guide consumers toward more sustainable choices, various eco-certifications and labels have emerged. These certifications ensure that home textiles meet certain environmental and social standards.

- Global Organic Textile Standard (GOTS): GOTS is one of the most recognised certifications for organic textiles, ensuring that products are made from organic fibres and manufactured under socially and environmentally responsible conditions.

- OEKO-TEX Standard 100: This certification ensures that textiles are free from harmful chemicals and safe for human health.

- Fair Trade Certification: This label indicates that the product was made under fair labour conditions, ensuring that workers are paid fairly and work in safe conditions.

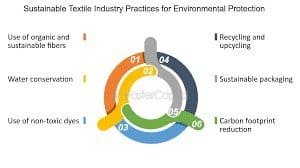

Source: Faster Capital

4.2. Minimalism and Eco-Friendly Design

The trend toward minimalism in home decor has contributed to the adoption of sustainable textiles. Consumers are increasingly opting for timeless, durable designs made from eco-friendly materials that require less frequent replacement.

- Timeless Aesthetic: By focusing on neutral tones, quality craftsmanship, and simple designs, consumers are embracing longevity in home textiles.

- Modular and Convertible Products: Textiles designed to serve multiple purposes (e.g., bed linens that can also serve as throws) promote longevity and reduce the need for multiple purchases.

4.3. Smart Textiles and Innovations

The future of home textiles also includes the integration of smart technologies. These textiles can enhance comfort, functionality, and sustainability. For example:

- Self-Cleaning Fabrics: Textiles with self-cleaning properties, made possible by advances in nanotechnology, reduce the need for washing, saving water and energy.

- Solar-Powered Fabrics: Fabrics integrated with solar cells could be used in future home textiles to power small appliances or provide lighting.

Source: Textile Learner

5. Challenges and Future Directions

Despite significant progress, several challenges remain in the quest for sustainable home textiles:

- Cost: Sustainable textiles, due to the use of organic or recycled materials and eco-friendly manufacturing processes, often come at a higher price point, making them less accessible to a broader range of consumers.

- Supply Chain Transparency: Ensuring the sustainability of the entire supply chain—from raw material sourcing to final product manufacturing—is complex. Many companies struggle to maintain transparency and traceability.

- Consumer Awareness: While demand for sustainable textiles is growing, many consumers remain unaware of the environmental and social implications of their textile choices. Increased education and labelling transparency can help address this.

Conclusion

The shift towards sustainable practices in home textiles is a positive and necessary step in reducing the environmental footprint of the textile industry. With advancements in material innovation, eco-friendly production techniques, and growing consumer demand for sustainability, home textiles are becoming more aligned with a circular, eco-conscious economy. However, challenges such as cost, supply chain transparency, and consumer education need to be addressed to make sustainable home textiles accessible to a wider audience. As technology and consumer awareness continue to evolve, the future of sustainable home textiles looks promising, offering a more environmentally friendly and socially responsible alternative for modern living spaces.