Have you ever wondered about that soft, absorbent rectangle hanging in your bathroom? The humble towel has come a long way from its origins in ancient Turkey, where the first woven towels were created in Bursa in the 17th century. These early Turkish towels, known as peshtamal, were flat-woven pieces used in hammams (public baths) and would later evolve into the fluffy, absorbent towels we know today.

The towel industry has grown into a multi-billion dollar global market, driven by both household and institutional demands. From luxury hotels to everyday homes, towels are an essential part of human life, serving various purposes, from drying off after a shower to cleaning up spills in the kitchen.

Types of Towels and Materials

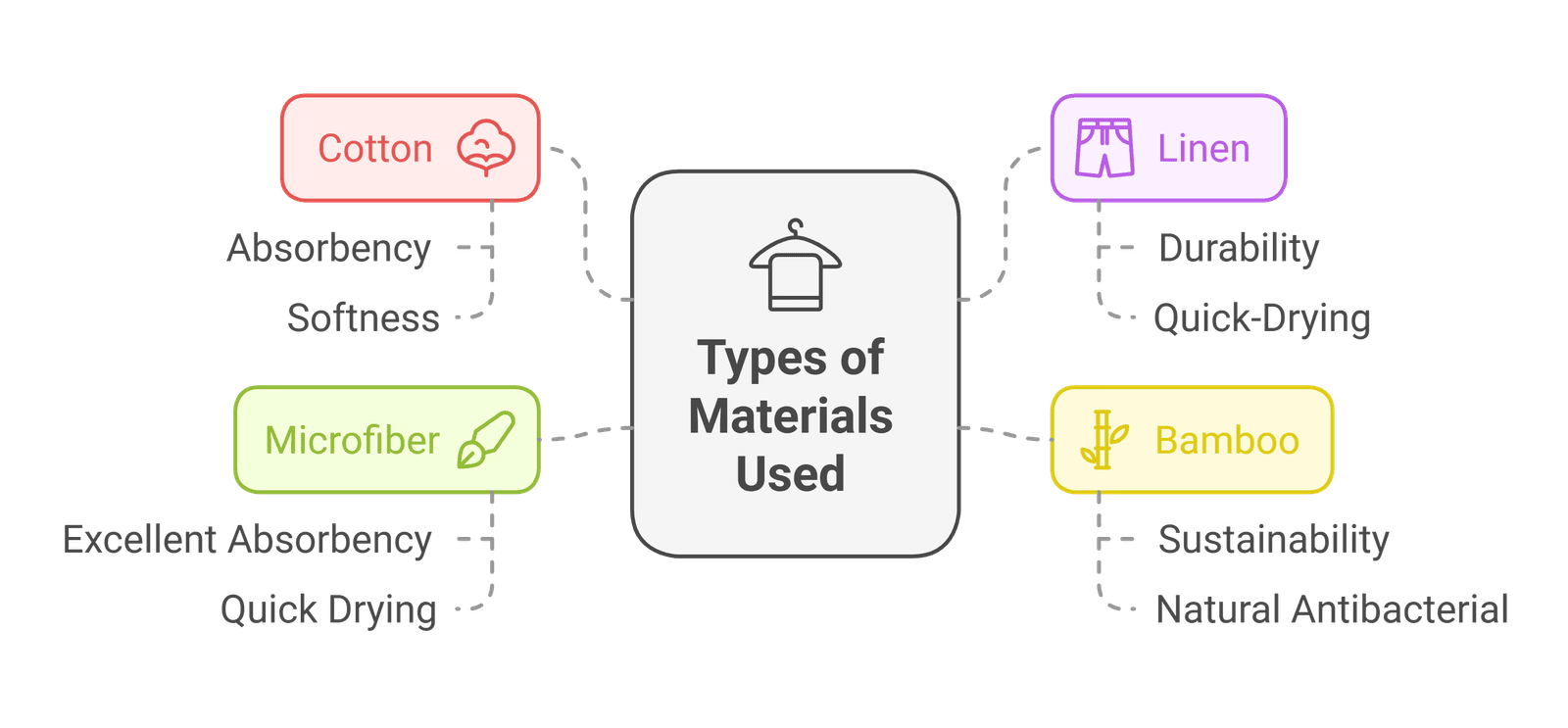

The world of towels is surprisingly diverse. Bath towels, hand towels, beach towels, kitchen towels, sports towels, and industrial towels each serve specific purposes. The material choice largely depends on the intended use. Cotton remains king in towel production, with several varieties leading the pack:

Egyptian Cotton is prized for its extra-long staple fibres, creating towels that are both durable and luxuriously soft. Turkish Cotton offers quick-drying properties while maintaining softness. Pima Cotton, grown in the Americas, rivals Egyptian cotton in quality. Bamboo fibre towels have gained popularity for their antimicrobial properties and eco-friendliness. Microfiber towels, made from synthetic materials, are popular in sports and cleaning applications due to their superior absorption and quick-drying capabilities.

The Journey from Fiber to Towel: Production Steps

The production of towels is a fascinating journey that combines traditional textile knowledge with modern manufacturing technology. Let’s walk through each stage of this intricate process.

The journey begins in the Fiber Preparation department, where raw materials arrive in compressed bales. These bales are carefully opened and mixed to ensure consistent quality throughout the production. The fibres go through a series of cleaning processes where advanced machines remove dirt, debris, and other unwanted materials. This stage is crucial as it sets the foundation for the quality of the final product.

Next comes the Carding process, where the cleaned fibres are transformed into a continuous web. Think of it as combing hair – the fibres are gently separated and aligned parallel to each other. This process removes any remaining impurities and short fibres, creating a uniform, continuous strand called a sliver. Modern carding machines can process substantial amounts of fibre per hour, making this stage both efficient and crucial for quality.

The Drawing and Combing stages follow, where multiple slivers are combined and drawn out to create an even more uniform strand. Imagine pulling and stretching a rope to make it thinner and more even – that’s essentially what happens here. For premium towels, an additional combing process removes shorter fibres and ensures superior quality. This stage is where the foundation for the towel’s eventual softness and durability is laid.

The Spinning process transforms these prepared fibres into actual yarn. Using either ring spinning or rotor spinning methods, the fibre strand is twisted and wound onto bobbins. Different types of yarn are created for different parts of the towel – some for the base structure and others for the loops that give towels their characteristic absorbency.

Before weaving begins, the yarn goes through Weaving Preparation. This involves creating large beams of parallel yarns (warping) and applying a protective coating (sizing) to prevent breakage during weaving. It’s like preparing your ingredients before cooking – everything needs to be just right before the main process begins.

The Weaving stage is where the towel truly begins to take shape. Modern looms weave three different yarn systems together – the ground warp, ground weft, and pile warp. This creates the base fabric and the loops that give towels their absorbent quality. The process requires precise control to ensure uniform pile height and proper fabric construction.

After weaving comes Wet Processing, a series of chemical treatments that prepare the towel for its final form. The fabric goes through preparation, bleaching, and dyeing processes. This stage determines the towel’s colour and begins to develop its absorbent properties. The fabric might be processed in large continuous lines or in batch-type machines, depending on the specific requirements.

The final stage is Finishing, where the towel gets its ultimate look and feel. This includes both mechanical processes like cutting the pile to a uniform height and brushing for softness, as well as chemical treatments for special properties like extra softness or quick-drying abilities. The towels are then cut to size, hemmed, and packaged for distribution.

Throughout the entire process, quality control measures ensure that the towels meet specific standards for weight, absorbency, color fastness, and durability. Modern manufacturing facilities use automated systems and computer controls to maintain consistency and efficiency in production

Machines Used in Production:

The towel manufacturing process relies on various specialised machines:

- Spinning Machines: Convert fibres into yarn.

- Warping Machines: Arrange threads onto beams.

- Dobby Looms: Weave fabric with intricate patterns.

- Dyeing Machines: Facilitate uniform dye application.

- Cutting Machines: Precisely cut fabric into towel sizes.

Leading manufacturers of these machines include brands like Rieter, Saurer, and Itema, which are known for their advanced textile machinery.

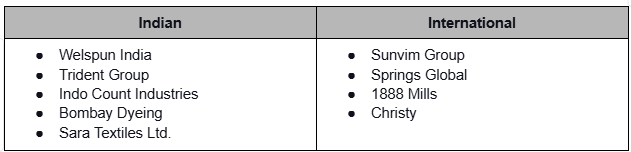

Leading Manufacturers

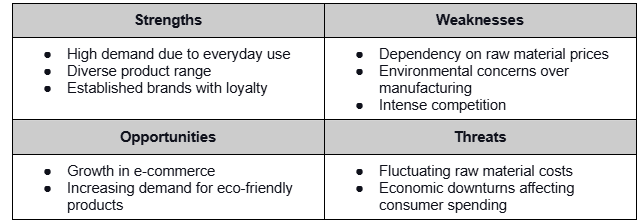

SWOT Analysis

The towel industry continues to evolve, balancing traditional manufacturing expertise with modern innovations. Whether it’s the integration of smart technologies, the development of more sustainable production methods, or the creation of advanced materials, the future of towel manufacturing looks promising.

From ancient Turkish hammams to modern smart fabrics, towels have remained an essential part of human life. Understanding their production process not only gives us an appreciation for the complexity behind these everyday items but also helps us make more informed choices as consumers.

The next time you dry off after a shower, remember the journey your towel has made – from a humble cotton plant to the sophisticated product in your hands, shaped by centuries of innovation and craftsmanship.